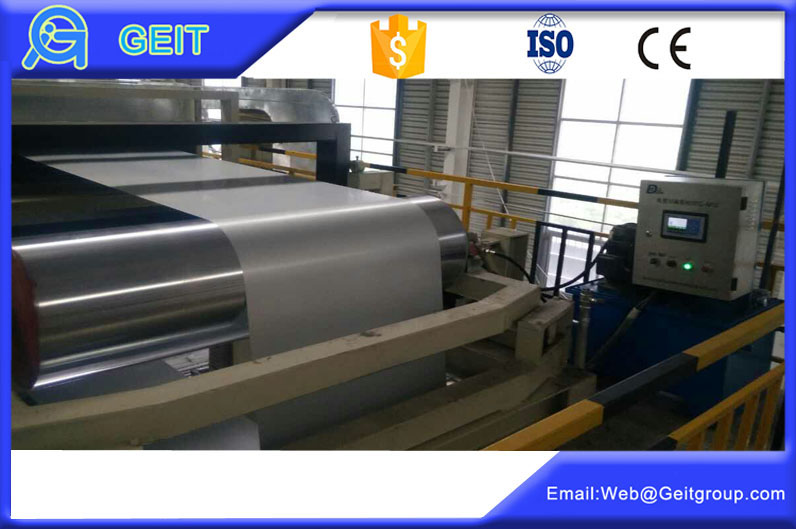

Electro-hydraulic servo deviation-correcting system

This system applies the probe-type infrared photoelectric detection technology to closely monitor the production lines of non-transparent metal and non-metal strips, trace the lateral deviation and servo control the deviation. The system outputs standard electrical signal, which is calibrated, amplified and transformed through PID controller and power amplifier and then amplified and transformed to pressure and flow signals through the servo proportional valve to output, so as to control the servo cylinder to transform the electricity to hydraulic energy and output. The system quickly, powerfully, steadily and sequentially drives the uncoiler, coiler or deviation-correcting machine frame to move laterally and precisely control the deviation of strips according to the set pressure and flow values of the hydraulic station, so as to make the strips overcome all external factors during the production process. The system is widely applied to the production lines of rolling, annealing, acid washing, plating, color coating, tension leveling, shearing and re-coiling of metal plates, strips and foils, e.g., plain carbon steel, stainless steel, aluminum, copper plates and strips.

Characteristics

1.Mechanic-electronic-hydraulic integration and high integration level

2.Small signal input and high power output

3.New generation of servo-proportional control and high automation degree

4.Infrared modulated light or inductance and good synchronized regulation and anti-interference performance

5.Fast dynamic response and high control precision

7.Stable performance and convenient maintenance

8.Small system power consumption and long service time

Technical Parameters

1.Working power source of the hydraulic system: AC380V, 50HZ, 5A/AC220V

2.Power source for instrument-electric control: DC 24V 4.5 A

3.Power source for button light: DC 24V, 20mA

4.Opto-electronic signal output: DC 1-10V

5.Amplifier output: DC 0-±10V

6.Amplifier input impedance: 50KΩ or 250Ω

7.Servo value output:

9.System rated flow: 30 L/min

10.Working medium: HL46# anti-wear hydraulic oil

11.Cleanliness of oil fluid: NAS1638-8-10

12.Temperature of oil fluid: 20-50℃

13.Linear speed of strips: 5-200m/min

14.System bandwidth: 3-5Hz

15.Control precision: ±1mm

Please feel free to give your inquiry in the form below.We will reply you within 24 hours