Organic coating line is also called color coating line(CCL). It is using steel coil as the substrate, than make the color coated sheet by first going through surface pre-treatment, then coated with one or more layers of liquid orgainc coating by roll coating, and finally baking and cooling to achieve the steel strips surface with high-durability, corrosion-resistance and formability. and the repainted steel sheet is excellent in the performance of decorative,forming,anti-corrosion,strong adhesive force the coating,as well as keeping color fresh for a long period of time.

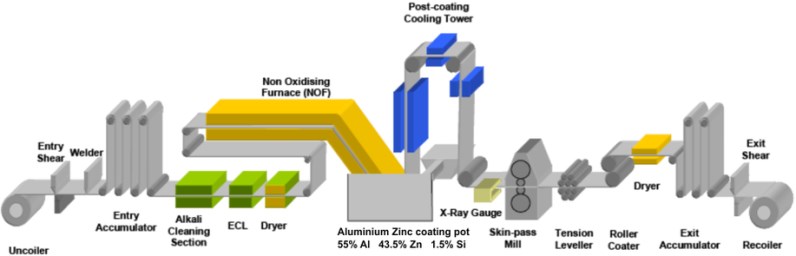

The following steps take place on organic coating line:

1. Stitching the strip to the previous coil

2. Cleaning the strip

3. Power brushing

4. Pre-treating with chemicals

5. Drying the strip

6. Applying primer on one or both sides

7. Curing (often only 15 to 60 seconds!)

8. Cooling the strip

9. Top coating on one or both sides

10. Second curing

11. Cooling down to room temperature

12. Rewinding of the coated coil

Technical parameter of organic coating line:

| material | Electric-galvanized coil, hop-dip galvanized coil, cold-rolled coil, hot-dip Al-Zn coil etc |

| Width of steel coil | 500-1750mm |

| Thickness of steel coil | 0.1-1.5mm |

| Outer diameter of steel coil | Maxφ2000mm |

| Inner diameter of steel coil | Φ500mm |

| Process speed | 25-180m/min |

| Thickness of coating | 5-30μm for the single-layer dry film on the front face (regulated as required) |

| 5-20μm for the single-layer dry film on the back face (regulated as required) | |

| Production capacity | 100,000-250,000t/year |

| Energy type |

Electric, gas, liquefied petroleum gas, coal gas etc |

Color coated steel sheet (PPGI & PPGL) is widely used in:

Building

Transport

Home Appliances, such as the side door plate of refrigerators, shell of DVDs, air conditioners and washing machines.

Solar Energy

Furniture

Please feel free to give your inquiry in the form below.We will reply you within 24 hours